About our Printed Circuit Board Design Services

We provide high-end PCB design services.

Our engineering teams serve a range of clients, from worldwide industry leaders to start-ups, in numerous industries.

Our added value lies in our ability to offer fully customized solutions: from rapid projects (a few days) to long-term projects where we design the whole system. Indeed, in addition to the PCB, we cover all the areas of electronic system design, which includes semiconductor design (FPGA, IP, ASIC/SoC) and OS based (or bare metal) embedded software development.

We can take on your PCB design project through different modes: work packages inside our electronic design houses, consultancy, or dedicated design center.

PCB Design Capabilities

Our PCB design capabilities include:

Digital design – microcontroller, MPU, SoC, FPGA, CPLD

Analog design – acquisition chain, sensors, filters

Communication bus – Ethernet, SATA, PCIe, USB, CAN

Wireless: Bluetooth, Wifi, LoRa, RFID, NFC

PCB: multilayer, HDI, high frequency

Service offerings

Our service offerings include:

- Specifications development,

- Architecture,

- BoM selection,

- Implementation,

- Project Management,

- Project Plans,

- Turnkey,

- Design files,

- Documentation,

- Test development.

PCB Design Project

Typical project follows these steps:

- The client sends us an initial specification (or we can assist him/her to write it).

- We design a response to a call for tenders presenting the contemplated board architecture and its main related components.

- Once the architecture is validated, we go on to the schematics design step. To make these schematics approved, we provide a whole set of files (BoM, specification etc.).

- We then start the layout part, sometimes with the support of a subcontractor.

- We check that the routing is compatible with the schematics and that we are answering the requirements specification, for instance in terms of electronics boards’ throughput.

- Simultaneously, we carry out many simulations on the board itself to approve, support or find the adequate routing.

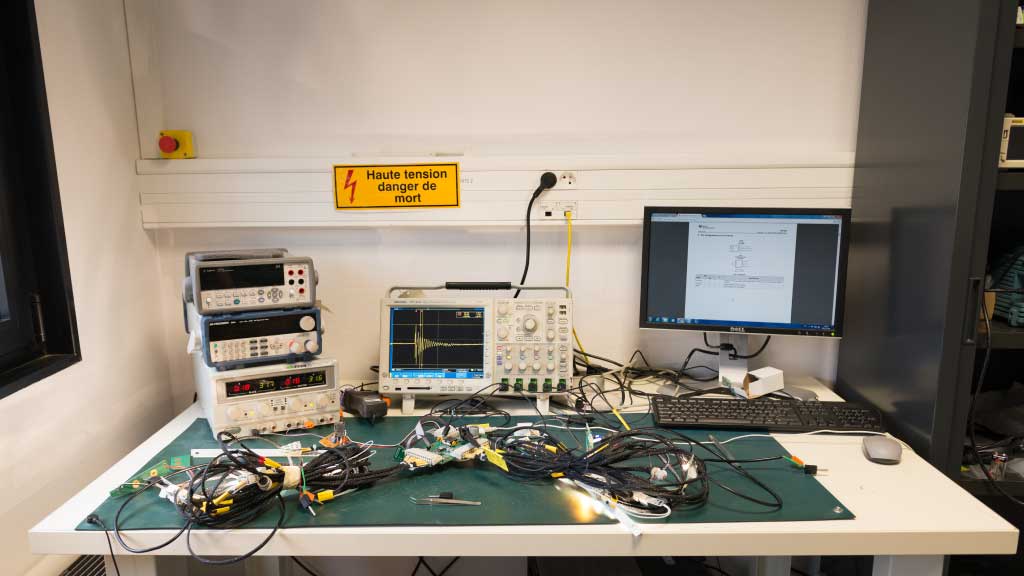

- The PCB board is usually manufactured twice, the first one being used for the various tests in laboratory. Once everything is approved, we start the second board fabrication. There, we simply check that it has been realized properly and we put the software inside.

- We then deliver the project to the client.